ABSTRACT

Anaerobic digestion is a technology which exploits the ability of anaerobic bacterial consortia to solubilize, degrade and produce a large amount of biogas from a wide variety of organic matter. This work covers the environmental and social aspects of the management of the faecal matter of fifteen people recovered from a septic tank. The sizing of the pit was carried out with a view to recovering the biogas which will be used for cooking food and thus will improve the health conditions of rural populations. The estimated production of this biogas is 141.25 𝑚3 after one year. This annual production is equivalent to five liquefied butane bottles of 12.5 kg or 172 kg of firewood. By recovering this amount of biogas, 84.75 𝑚3 of methane is avoided in the atmosphere after one year.

Introduction

In rural areas of developing countries, cooking food is highly dependent on biomass. This dependence on biomass accentuates deforestation, which has a negative impact on the environment (global warming). The fumes generated by the combustion of the biomass have a consequence on health (the eyes, the nose or the throat can be irritated, asthma and other respiratory problems can be aggravated). Thus, the development of energy sources, particularly renewable ones, would not only protect the environment, but also constitute an opportunity to improve the living conditions of the poorest families. Biogas, which is a product from anaerobic digestion, is mainly composed of methane (CH4) and carbon dioxide (CO2), with a minority of sulfur compounds (𝐻2𝑆, mercaptans (R-SH)) and nitrogen compounds (ammonia, nitrogen) is also one of the new energy players (Dupont, 2010). It is a gas whose use helps to protect the environment while improving hygiene.

Human fecal matter received in septic tanks constitutes a potential source of free and very interesting renewable energy which so far is untapped.

The main objective of this project is to size a biogas production unit from the septic tank of a dwelling house for fifteen people, supplied by the toilets.

1- Materials and methods

From the productivity of human faecal matter, the hydrogen potential (PH) and the C/N (carbon/nitrogen) ratio of a septic tank in a tropical environment, calculations will be made.

a) Study environment

The humid tropical zone constitutes the vastest climatic unit existing on the surface of the globe and the only one which is in one piece since it extends more or less symmetrically on either side of the equator. We can consider that the humid tropical zone in the broad sense covers the regions located at low latitudes, where the rain is abundant enough to allow their inhabitants to live on the products of non-irrigated agriculture, which excludes certain dry areas between the two tropics. It extends in total over 46°55′ of latitude, symmetrically on either side of the equator (from 23.5° north latitude to 23.5° south latitude) (Emmanuel Naah, 2002). This vast area actually embraces quite diverse natural environments which have in common only their high temperature throughout the year (average temperature of 20 to 30° C) (Emmanuel Naah, 2002). Where dense, evergreen forest exists with its countless species, we have one side of the humid tropics. The other is that of open forests, savannahs.

b) Septic tank and feces

In this project, the septic tank provides effective pre-treatment and liquefaction of waste from the toilets (faeces and toilet paper). Fecal matter is the residue of digestion, it is not absorbed and is rejected by the anus at the end of digestion. In the humid tropical zone, the diet is rich in plants, so the average mass of faecal matter will be taken as equal to 400 g per day with an average dry matter rate of 25% and an average volatile dry matter rate of 86 % (Joan Colon et al., 2015).

c) Septic tank biogas productivity

The average biogas productivity of human faecal matter will be taken as equal to 0.3 m3 of biogas/kg of stool volatile dry matter in the case where the faecal matter is mixed with urine (Joan Colón et al., 2015).

d) Substrate residence time

Given that the system operates in Mesophilic mode (digestion temperature between 25° C and 45° C) and that the faecal matter + water mixture is not homogeneous, the residence time of the substrate will be taken as equal to 60 days.

e) Daily production of biogas

Daily biogas production = Daily stool mass × number of people × Productivity × dry matter rate × volatile matter rate. The methane content of the biogas produced by a septic tank fed by the toilets will be taken as 60% (Joan Colón et al., 2015) because this biogas has the same characteristics as that from wastewater treatment plants.

f) Hydrogen potential (HP)

The hydrogen potential inside a septic tank has an estimated average value of 6.5 (Somorin, T. O., 2020). This average value does not correspond to the PH necessary for good development of bacteria in the septic tank, but remains very close to the optimal range which is 6.8 to 7.2.

g) C/N ratio

The average C/N ratio of human excrement is 10.5 (Joan Colón et al., 2015), which is far from the optimal values which are between 20 and 30. This is what somewhat justifies the low productivity into biogas from human faeces.

h) Choice of process

Table 1: Principal parameter of process

| Fashion Feeding | Substrate type | Number of steps | Temperature | Substrate residence time |

| Continued | Liquid | Single phase | Mesophilic (37 °C) | 60 days |

2- Results

a) Daily production of biogas

Daily biogas production = Daily stool mass × number of people × Productivity × stool dry matter rate

× Volatile mat

= 0,4×15×0,3×0,25×0,86

= 0,387 m3

b) Septic tank dimensions

The sizing of the septic tank will be done with the following considerations:

The average weight of human matter will be taken as 400 g per day and 7 L of water will be needed for hunting. Since human faecal matter contains on average 75% water, the density of human faecal matter will be taken as 900 kg/m3.

i) Dimensions of storage pit 𝑉𝑢 (Volume of pit uses)

The hydraulic retention time is 60 days, the house is habited by fifteen people whose average weight of faecal matter is 400 g/day.

With these considerations, the useful volume of the digester will be:

𝑉𝑢 = (7 + 0.4/0.9) × 60 × 15 = 6,700 𝐿 = 6.7 𝑚3.

ii) Dimensions of the total pit volume 𝑽𝒕

Assuming that the pit will be surmounted by a tank equivalent to one third of the useful volume for biogas storage, the total volume of the digester will be:

Vt = Vu+1/4 𝑉𝑢 = 6.7 + 6.7/4 ≈ 8.5 m3

Considering a parallelepiped-shaped digester, its dimensions will be: Length = 2.25 m; Width = 2 m and Height = 1.9 m.

iii) Manhole dimensions

The digester will be connected to a manhole, which will either extract the digestate or prolong the decomposition in order to facilitate the infiltration of the substrate into the sump. If the extraction option is chosen, the digestate can be valorized on the agricultural level, because the polluting load has been considerably reduced (the polluting load has been transformed into biogas). The volume of the manhole will be the same as that of the useful volume of the pit. Since the substrate is 60 days in the digester it will also stay in the manhole for 60 days. Thus, the volume of the manhole will be 6.7 m3, and the frequency of carry out the contents will be four months.

Considering a manhole with a parallelepiped shape, its dimensions will be: Width = 2 m; Length = 2.25 m and Height = 1.65 m.

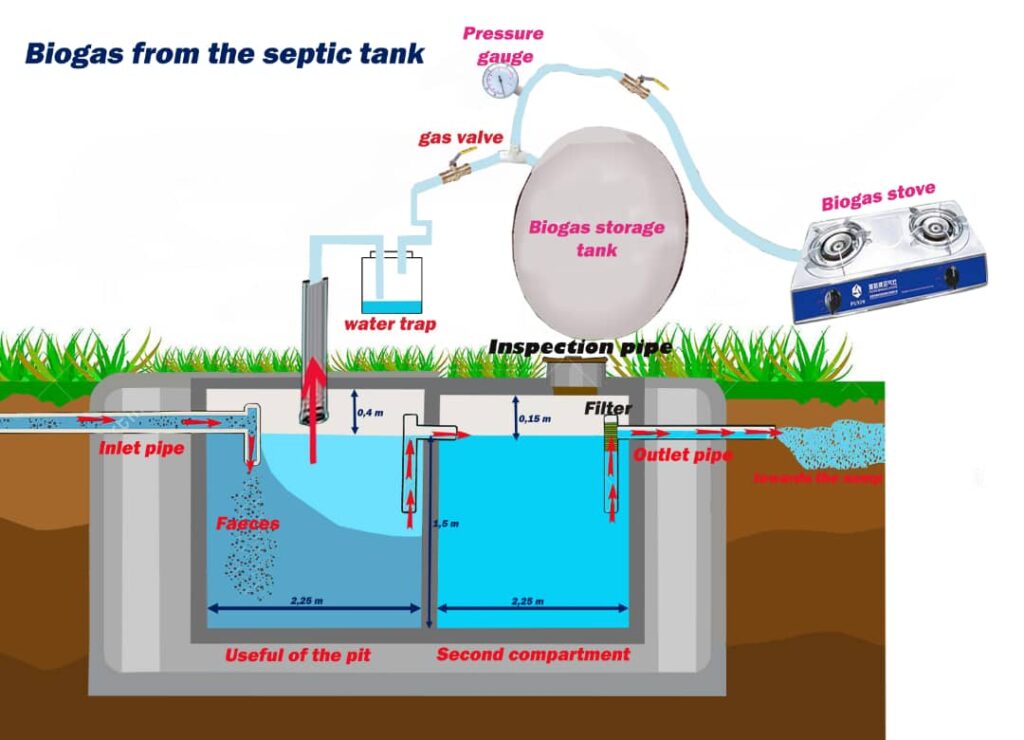

Figure 1: synoptic diagram of the project

3- Discussions

The daily biogas production obtained for this project is around 0.387 𝑚3. However, we know that a 12.5 kg bottle of butane is equivalent to 28.5 𝑚3 of biogas, for a biogas containing on average 60% methane. Indeed, the lower calorific value of butane is 13.6 kwh/kg, while that of a biogas containing 60% methane is around 6 kwh/𝑚3. Thus, to obtain a production equivalent to that of a 12.5 kg bottle of butane, it will take 28.5/0.387 ≈75 days, or two and a half months. This production also makes it possible to substitute 172 kg of firewood, because the calorific value of firewood is approximately 5kwh/kg.

Economically, this production can be estimated at 32,500 CFA francs after one year, considering that a bottle of butane costs 6,500 CFA francs on the market. The amount of biogas produced roughly corresponds to five 12.5 kg bottles of liquefied butane.

Environmentally, after one year 141.25 𝑚3 of biogas at 60% methane is recovered, i.e. 84.75 𝑚3 of methane that has been avoided in the atmosphere. On a social level, the use of biogas as an energy source for cooking food helps to avoid irritation of the eyes by the smoke from the wood fire and other respiratory problems.

4- Conclusion

The septic tank, included in an integrated management system for the energy recovery of human faecal matter, has interesting potential in terms of energy, economics and the environment. The anaerobic digestion technology used in this work reduces the environmental impact of faecal matter and improves the living conditions of inhabitants in rural areas.

The main objective of this work was to size a biogas production unit from the septic tank of a dwelling house for fifteen people, supplied by the toilets. In the end, it emerges that by recovering the faeces of fifteen people, we can produce biogas equivalent to five bottles of liquefied butane of 12.5 kg after one year in terms of gas or 172 kg of firewood. Heats up and prevent 84.75 𝑚3 of methane from being released into the atmosphere.

No human work being perfect, a limit of this work is the fact that the productivity of human faecal matter, its rate of dry matter and its rate of volatile dry matter are taken from the literature, but remain values obtained at the outcome of the experiments.

Bibliographic references:

- DUPONT, N. (2010).Valorisation du biogaz de fermentation : combustion catalytique. (Thèse de doctorat, Université Claude Bernard, Lyon I, France), p.1-6.

- EMMANUEL NAAH, (2002).Recherche et développement pour l’environnement en Afrique sub-saharienne, p. 975-980

- JOAN COLÓN et al. (2015). Energy for Sustainable Development 29, p. 57–64

- SOMORIN, T. O. (2020) Valorization of human excreta for recovery of energy and high-value products, 26 p